|

1.Overview:

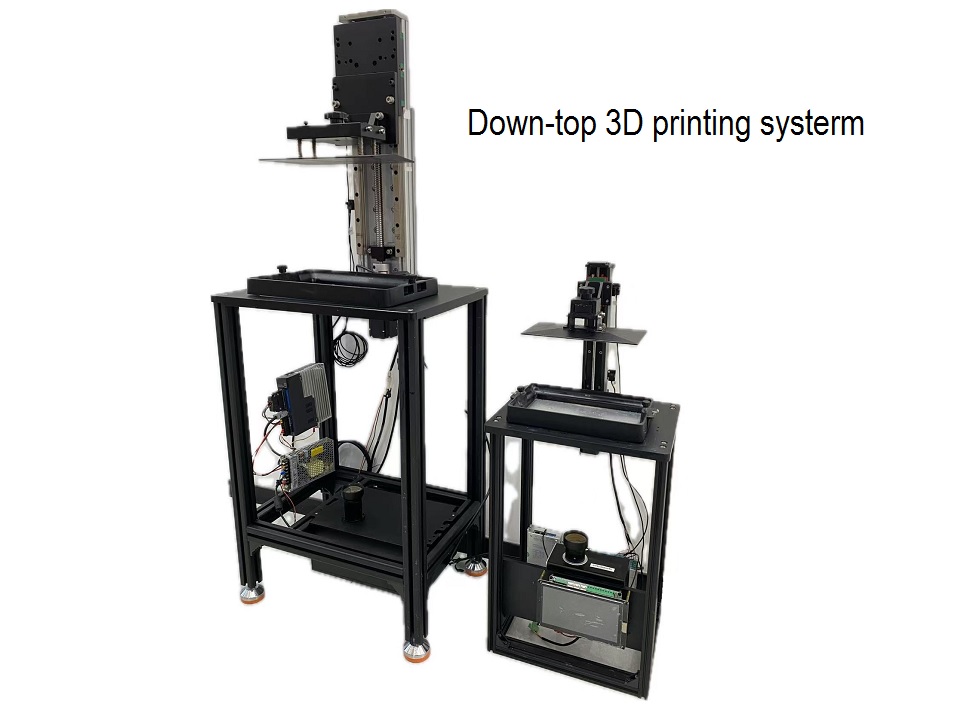

The Bottom-up 3D printing system achieves printing through direct control of the optical and mechanical systems through a PC. The system is designed in an open manner, including software development, structural design, and other reference designs. Customers can optimize the system based on their own process parameters; Suitable for prototype or material testing in the field of scientific research;

2.Features

Structural design:

The 3D printing system adopts the simplest structure; Ensure the reliability of the structure, and the printing format can be flexibly adjusted according to requirements;

Printing software:

Open various software functions and provide SDK for secondary development;

Hardware solution:

The PC controls the optical and motor through USB to achieve printing; No additional control board is required;

3.Application:

※Research field, material testing;

※Prototype testing;

※printing factory

4. Model

|

Model

|

PBS05-100

|

PBS07-75

|

|

Accuracy

|

100um

|

75um

|

|

Resolution

|

1920*1080

|

3840*2160

|

|

Area

|

192*108mm^2

|

288*162mm^2

|

|

Slice thickness

|

0.02-0.10mm

|

0.02-0.10mm

|

|

Support Files

|

SLC

|

SLC

|

|

Light Source

|

405nm/385 nm

|

405nm/385 nm

|

|

Machine size

|

765*355*290

|

1340*516*391

|

5 Machine size:

PBS05-100

PBS07-75

|